What is Telerozion?

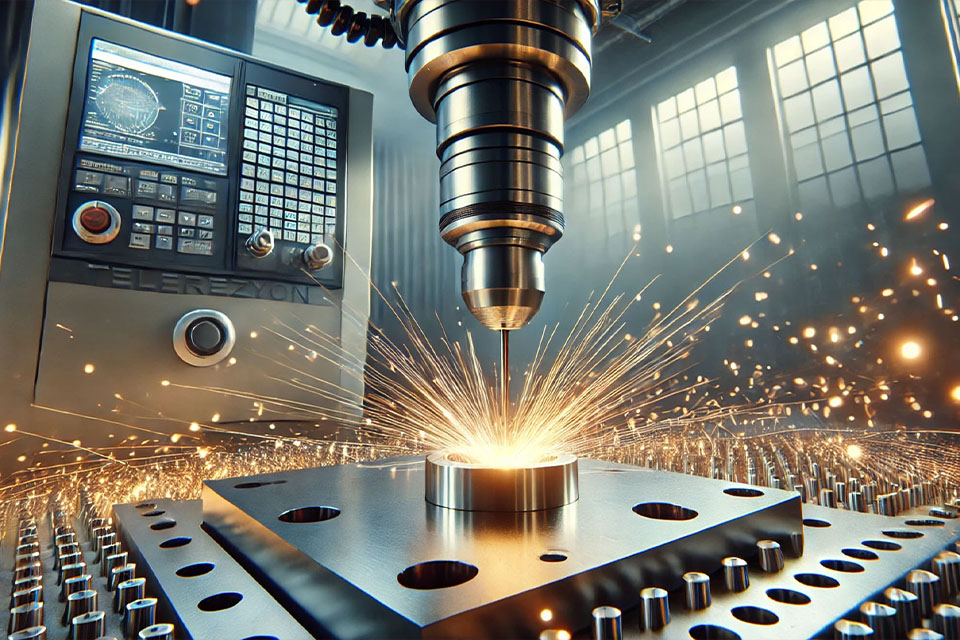

Telerozion is a cutting technology that works with the principle of electrical discharge. This method is used for high precision cutting and shaping of metal parts with particularly complex geometries. During the telerozion process, a thin wire electrode cuts the material with electric sparks and creates the desired form. Also known as "Wire EDM" (Electrical Discharge Machining). In this method, the material is eroded by creating electrical discharges between a thin wire electrode and the workpiece.

How Does Wire Erosion Work?

The wire erosion process basically consists of the following steps:

Wire Electrode: A thin wire, usually made of brass or copper, is stretched between two reels and moves continuously. This wire acts as an electrode.

Dielectric Liquid: The workpiece and the wire are immersed in a dielectric liquid (usually deionized water). This liquid allows the electrical discharges to occur in a more controlled manner and cleans the particles that form.

Electrical Discharges: High voltage is applied between the wire and the workpiece. When the wire and the workpiece get too close to each other, electric sparks occur between them. These sparks create very high temperatures on the surface of the workpiece, causing the material to melt and vaporize.

Cutting Process: The wire is moved precisely by the CNC (Computerized Numerical Control) system to create the desired shape. Since electrical discharges occur continuously, the material is eroded as the wire advances along the workpiece and the cutting process is completed.

Advantages of wire erosion:

High Precision: Wire erosion provides the ability to cut with very high precision. Tolerances at the micron level can be achieved.

Complex Shapes: Complex shapes and details that are difficult or impossible with traditional methods can be easily produced with wire EDM.

Hard Materials: Hardened steels, titanium, carbide, and other difficult-to-machine materials can be cut with wire EDM.

Clean Cut: Since there is no mechanical contact during the process, there is no burr or stress on the workpiece.

Wire EDM is widely used in a wide variety of industries:

Mold and Model Making: Plastic injection molds, casting molds, cutting molds, etc.

Aerospace Industry: Turbine blades, engine parts, etc.

Automotive Industry: Gears, injectors, etc.

Medical Devices: Implants, surgical instruments, etc.

Precision Mechanical Parts: Watch parts, electronic components, etc.

In summary, wire EDM is used for high precision, complex shapes and is a preferred method when hard materials need to be processed. It is an indispensable technology especially in areas such as mold and model making.

Teleerosion technology allows processing of details that are not possible with traditional processing methods. It is frequently preferred in mold production requiring high precision, special part manufacturing and projects requiring fine workmanship. This method can be effectively applied to various materials such as steel, copper and aluminum.

In addition, one of the biggest advantages of teleerosion is that thermal deformation is at a minimum level. This feature ensures that the highest quality results are obtained by preserving the structural integrity of the material.

If you want to learn more about teleerosion technology or discover solutions suitable for your projects, you can contact us.

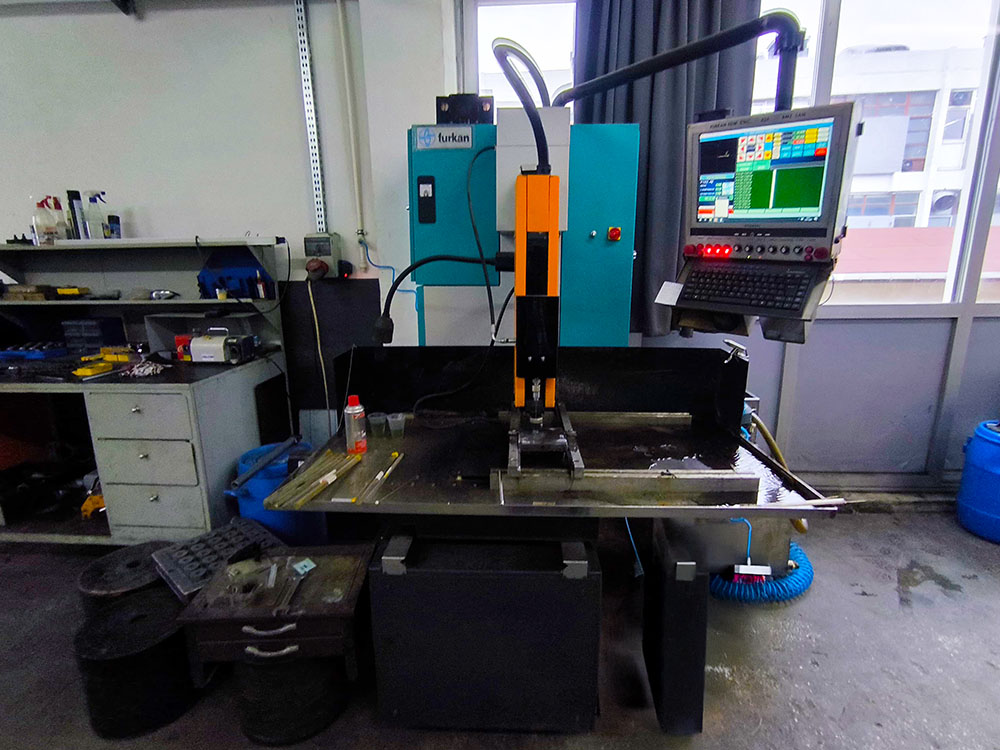

Our Machine Park